Ready to shipping

We can customize produce tool steels in based on quality and production facility requirement.

We ship our materials to customers either forged or milled surfaces which depends on customers requirement.

Marking and contents can be DIN, ISO, GB or designed by customers.

Premium tool / mould steels

We can produce plastic injection mould steels, based on the polishability and durability, different process route can be selected.

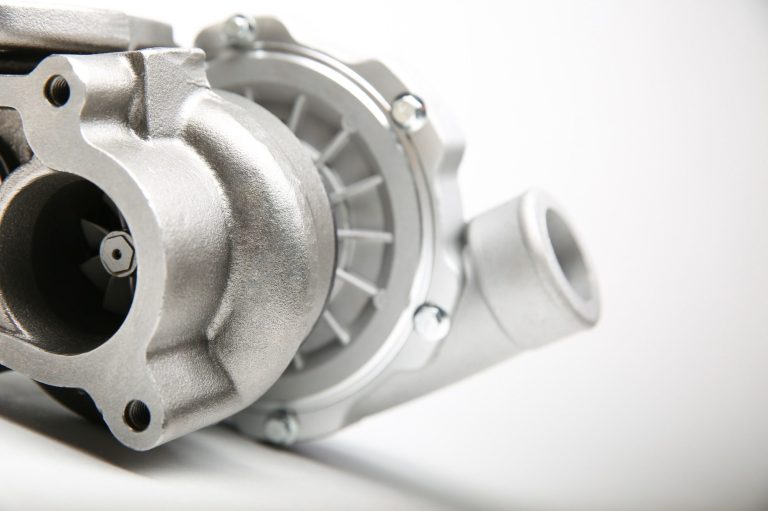

Hot work tool steel is our most advanced product. We have materials for high duty aluminum die casting or extrusion; Hot pressing tool steel for e-auto body parts; Hot forging tool steels for steel parts production.

Cold work tool steels for punching, deep drawing or bending with high C(carbon) and W(Tungsten) chemical compositions.

1.2343EAF / H11(OS300)

Hot-worked chromium-molybdenum alloy steel has excellent high-temperature strength and high toughness at high temperature. Due to its thermal fatigue resistance and hardenability, it can be used to make die-casting, extrusion and injection moulds, as well as ejector steel, hot-cutting blades and large plastic hard moulds that require wear resistance.

1.2343ESR / H11ESR(OS300ESR)

After ESR (electroslag remelting) with our special forging and heat treatment process, the products have extremely high impact resistance value and non-directionality.

The extremely high degree of purity renders the steel with higher polishability and better mechanical properties, which can be used for large and highly polished moulds with very high requirements. The products have excellent impact toughness and fatigue resistance, very suitable for large die-casting moulds.

1.2738 / P20+Ni(OS238)

Excellent machinability and polishability, and suitable for etching. Good hardenability due to the increased nickel content of about 1%. For large-size moulds.

Normally pre-hardened to 30-34HRC, and maximum to 38HRC if requested by customer.

1.2738mod.HH / similar XPM(OS248)

Especially suitable for large parts. Good polishability; good weldability; and nitridability. Homogeneous hardness from surface to center area.

Pre-hardened to 38-42HRC, more suitable for moulds with high service life and high requirements than 1.2738.

1.2738mod.HH ESR(OS258)

The ESR version of the OS248, has extremely high degree of purity and uniformity, and has excellent performance on the etching of the polishing machine. The hardness is very uniform from the surface to the center area. Pre-harden to 38-42HRC, higher toughness than age-hardened mould steel.

Suitable for large moulds with the highest polishing level, or the moulds with extremely fine etching patterns and high requirements.

1.2344EAF / H13(OS302)

Hot-worked chromium-molybdenum alloy steel has good high-temperature strength and high toughness at high temperature. Due to its thermal fatigue resistance and hardenability, it can be used to make die-casting, extrusion and injection moulds, as well as ejector steel, hot-cutting blades and large plastic hard moulds that require wear resistance.

1.2367mod.VAR (OS323)

A brand-new hot work mould steel with excellent comprehensive properties. It adopts the latest steelmaking, forging, and heat treatment technologies to significantly improve its resistance to thermal cracking and overall cracking resistance, and has excellent toughness and good high-temperature strength, excellent temper resistance, and good hardenability, high degree of purity and isotropy.

1.2714(OS 303)

Load-resistant mould steel with increased hardening depth and high wear resistance at high temperature.

Especially suitable for processing hard steel and jig of forging press, moulds of all sizes of upper and lower punching dies, and all types of cavities.Can be pre-hardened or delivered in annealed condition.

1.2379 / D2(OS401)

High chromium, ledeburitic cold-work tool steel with molybdenum and vanadium. The addition improve edge retaining and deep hardening properties. Good dimensional stability.

Excellent wear resistance due to the ledeburitic structure. Very good compression strength with sufficient toughness.

1.3343 / M2(OS501)

Tungsten-molybdenum general high-speed steel. The steel has the advantages of fine and uniform carbide, high toughness and good wear resistance.

It is a high-alloy steel containing a variety of alloying elements, which belongs to the Lyderimite type of steel and occupies an important position in cold work tool steel.

© Copyright Oestlich Material Science Group. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.